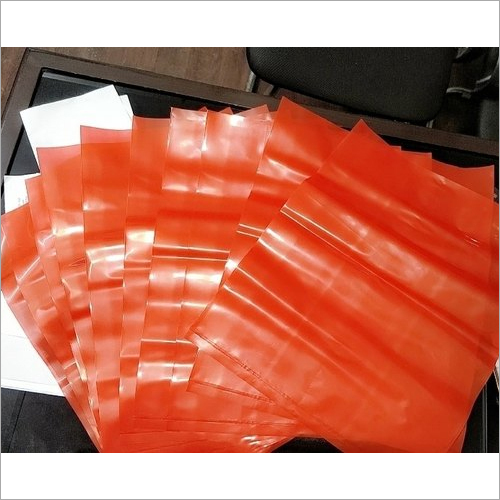

LDPE Plastic Bag

LDPE Plastic Bag Specification

- Material

- LDPE (Low Density Polyethylene)

- Surface Handling

- Smooth

- Handles

- Without Handles

- Feature

- Moisture Proof, Durable, Flexible

- Size

- Customized sizes available

- Color

- Transparent or as required

- Use

- Packaging, Storage, Food, Industrial Applications

- Chemical Resistance

- Good resistance to most chemicals

- Bag Type

- Flat, Gusseted, or Perforated

- Transparency

- High

- Eco-Friendliness

- Recyclable

- Printing

- Available on request

- Closure Type

- Open or Self-Sealing

- Tear Resistance

- Standard to High, as per requirement

- Thickness

- 25 to 100 microns or customizable

- Temperature Tolerance

- Suitable for -40°C to +80°C

About LDPE Plastic Bag

LDPE Plastic Bag is used for food packaging and frequently uses low-density polyethylene polymers. Short, branching chains that are thinly spaced apart and have a low density are used to create the LDPE polymer. As a result, stretch wraps, shopping bags, and conventional plastic bags are frequently made from LDPE. Apart from this, LDPE Plastic Bag is simple to process. Because it is soft, flexible, and has excellent impact resistance, especially at low temperatures, this plastic bag is advantageous.Product details

| Pattern | Plain |

| Usage/Application | Packaging |

| Micron | 51+ |

| Brand | As per requirement. |

| I Deal In | New Only |

| Virgin Quality | 100% |

| Material | LDPE |

| Thickness | 51+ microns |

Customizable Packaging Solutions

Our LDPE Plastic Bags can be tailored to meet the specific needs of various industries, offering flexibility in size, thickness, and color. Choose from flat, gusseted, or perforated bag types and select closures ranging from open to self-sealing. High transparency and smooth surface handling make them suitable for both branding and practical storage uses.

Reliable and Safe for Multiple Applications

Designed for use in food, packaging, storage, and industrial sectors, these LDPE bags ensure safety and durability. They are moisture-proof, provide good chemical resistance, and tolerate wide temperature ranges. These features make them suitable for storing sensitive materials and maintaining product integrity during transport or storage.

FAQs of LDPE Plastic Bag:

Q: How are LDPE Plastic Bags customized to fit unique packaging needs?

A: LDPE bags can be tailored in size, thickness (from 25 to 100 microns), color, bag type, and closure options to suit specific customer requirements. You can request printing and select from flat, gusseted, or perforated designs for optimal usage.Q: What makes these LDPE Plastic Bags suitable for food and industrial applications?

A: The bags are made from food-safe Low Density Polyethylene, boast high moisture and chemical resistance, and tolerate temperatures ranging from -40C to +80C. This makes them ideal for various storage and packaging scenarios in both food and industrial sectors.Q: When should perforated or gusseted LDPE bag types be used?

A: Perforated bags are beneficial when items require ventilation or easy tearing, while gusseted bags allow greater capacity and fit for bulkier or irregularly shaped products. Flat bags are suitable for standard packaging and storage needs.Q: Where are LDPE Plastic Bags commonly supplied and distributed in India?

A: These bags are supplied by distributors, manufacturers, traders, and suppliers across India, catering to packaging, food, retail, industrial, and many other sectors nationwide.Q: What is the process for ordering custom LDPE Plastic Bags?

A: Customers can begin by specifying desired dimensions, thickness, type, clarity, closure, and printing requirements. Manufacturers will provide samples or prototypes before mass production, ensuring all customer expectations are met.Q: How does the eco-friendly nature of LDPE bags benefit users?

A: LDPE Plastic Bags are recyclable, reducing environmental impact and promoting responsible usage. This sustainable feature is especially valuable to businesses and individuals looking to adopt greener packaging solutions.Q: What are the main advantages of using LDPE Plastic Bags for packaging?

A: Benefits include excellent moisture and chemical resistance, durability, flexibility, high transparency, and the ability to customize virtually every aspect of the bag to suit different product types and branding needs.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in LD Plastic Liner Bags Category

Colored LD Liner Bags

Size : As per requirement / Customizable

Handles : Other, Without Handle / Flat Seal

Feature : Other, Leak Proof, Moisture Resistant, Durable, Recyclable

Color : Blue, Yellow, Green, Red, Black, White, Transparent, Custom Colors

Surface Handling : Other, Smooth / Plain

Material : Other, Low Density Polyethylene (LDPE)

MITTAL POLYMERS

GST : 07COQPM4512R1Z6

GST : 07COQPM4512R1Z6

SHED NO. C-14, DSIIDC INDUSTRIAL COMPLEX, ROHTAK ROAD,New Delhi - 110041, India

Phone :08045812211

|

|

MITTAL POLYMERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry